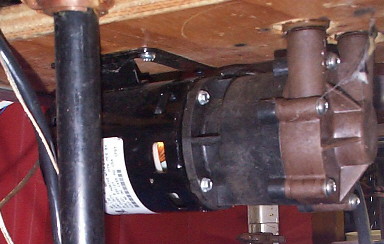

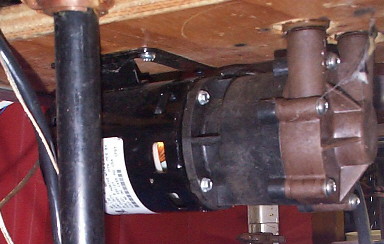

Magnetically Coupled Pump

Magnetically Coupled Pump Magnetically Coupled Pump

Magnetically Coupled PumpThe parts in contact with wort in this pump are made from the plastics Ryton or Kynar. This is a magnetically coupled pump. There are two major benefits to this type of pump for the home brewer. First there is no shaft entering the pump, hence no seal to leak. Don't be fooled into thinking that if you don't observe liquid leaking from the seal that it's OK. It could be sucking in air. It is very undesirable to have HSA (Hot Side Aeration) when brewing. I can't imagine a better way to create HSA than to have the impeller of a pump beating air into 150 degree wort for an hour and a half at nearly 3000 RPM. The second benefit is the ease in controlling the flow rate. By restricting the outlet with a simple ball valve you've created a simple flow control. The pump I chose is the March MDX-MT3. It's rated for 200 degrees F, has 1/2" NPT male connections, can flow 7.2 GPM at a 3 foot lift and has a 1/25 HP motor. I ordered it from MOVING BREWS, their part number is 8044MM.

Polyethylene tubing is used to connect the mash tun pick-up to the pump inlet. The standard vinyl tubing will collapse at mash temperatures and starve the pump. Polyethylene tubing is a milky white color and somewhat flexible. Using plastic tubing insures you are not putting extra stress on the pump housing.